February 1, 2024

Click to download the white paper as a pdf

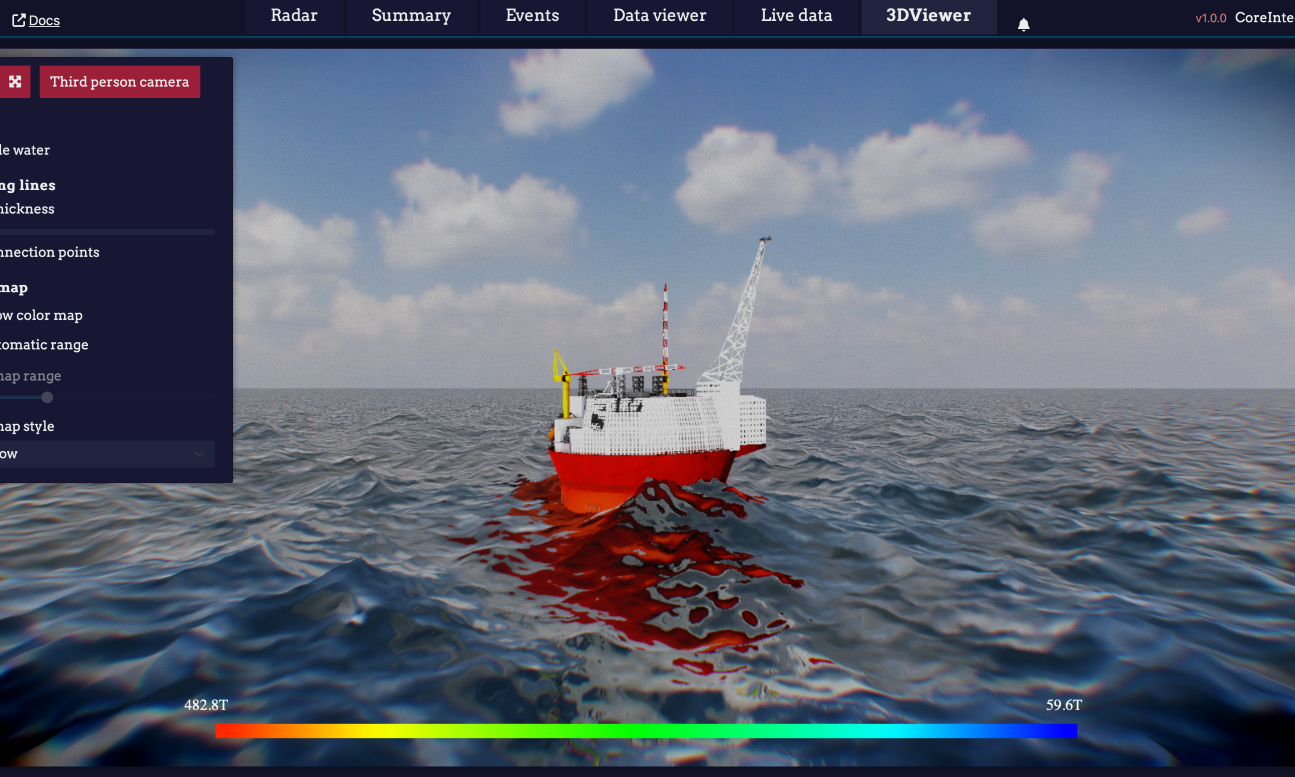

Mooring lines are essential for the safe and reliable operation of any floating offshore asset. They are designed to keep an asset in place for up to 30 years, even in harsh environments and when subjected to extreme events. However, mooring lines are not immune to failure. They can suffer from various forms of damage, accidents and degradation that can compromise their integrity and performance. In this article, we will explore the causes and consequences of mooring line failures, and what you can do to keep your mooring system safe.

Mooring line failure is more common than you might think. According to a study by DNV, the average mooring line or anchor frequency of failure is reported as 1.23E-03 per year, while a Granherne study found that across 33 floating production storage and offloading (FPSO) vessels, 150 mooring lines had to be repaired or replaced over a ten-year period. The consequence is that for FPSOs with multiple mooring lines, between one and two mooring system failures have occurred per year since 2001. In reality, under-reporting means the situation may be even worse.

Mooring line failure can have serious consequences for offshore operations. It can lead to loss of station-keeping, damage to the asset and the environment, increased operational costs, and reduced production. For example when the Gryphon Alpha FPSO lost four of its ten mooring lines in 2011, line repair and replacement was reported to have cost around $1.8 Bn.

What causes mooring line failure?

Mooring lines have to put up with a lot:

- Wear and abrasion: This can occur when mooring line components rub against one another, against the vessel, or against the seabed. Wear will reduce the cross-sectional area and the strength of the line, as well as potentially increase drag and tension.

- Corrosion and marine growth: Mooring lines can degrade quickly depending on metocean conditions. Corrosion can both weaken lines and increase drag. Marine growth can accelerate corrosion and increase mooring line drag and weight, which can affect a line’s natural frequency and fatigue life.

- Fatigue: The fatigue analysis done at the design stage is a simplified version of what the lines actually experience in real life. Different load cycles, wave spectra, and environmental conditions can result in higher fatigue damage than expected. In addition, lines are often subject to out-of-plane bending at fairleads and chainstoppers, which can dramatically accelerate the time to failure, as famously happened on the Girassol CALM buoy.

- Faulty components and materials: Mooring line materials, be they chain, wire, or rope, are subject to quality control and testing. However, even tiny imperfections can grow into large problems over the design life of the asset. For instance, cracks, pits, or fractures can initiate and propagate in the line, leading to sudden failure.

- Manufacturing and installation errors: Mooring lines often consist of multiple components, such as shackles, swivels, connectors, and clamps. Each additional component adds complexity and potential for things to go wrong. At one end of the scale, this may simply be bolts not being tightened adequately or anchors embedded with too much force. However, more extreme errors are possible, such as mooring lines being installed upside down when designer drawings are not properly followed by the installation contractor.

- Damage and accidents: With the best intention in the world, accidents still happen. Be it equipment dropped overboard, or fishing trawlers getting nets entangled, mooring lines can be exposed to unexpected and excessive loads that can cause them to break or snap.

How to prevent mooring line failure?

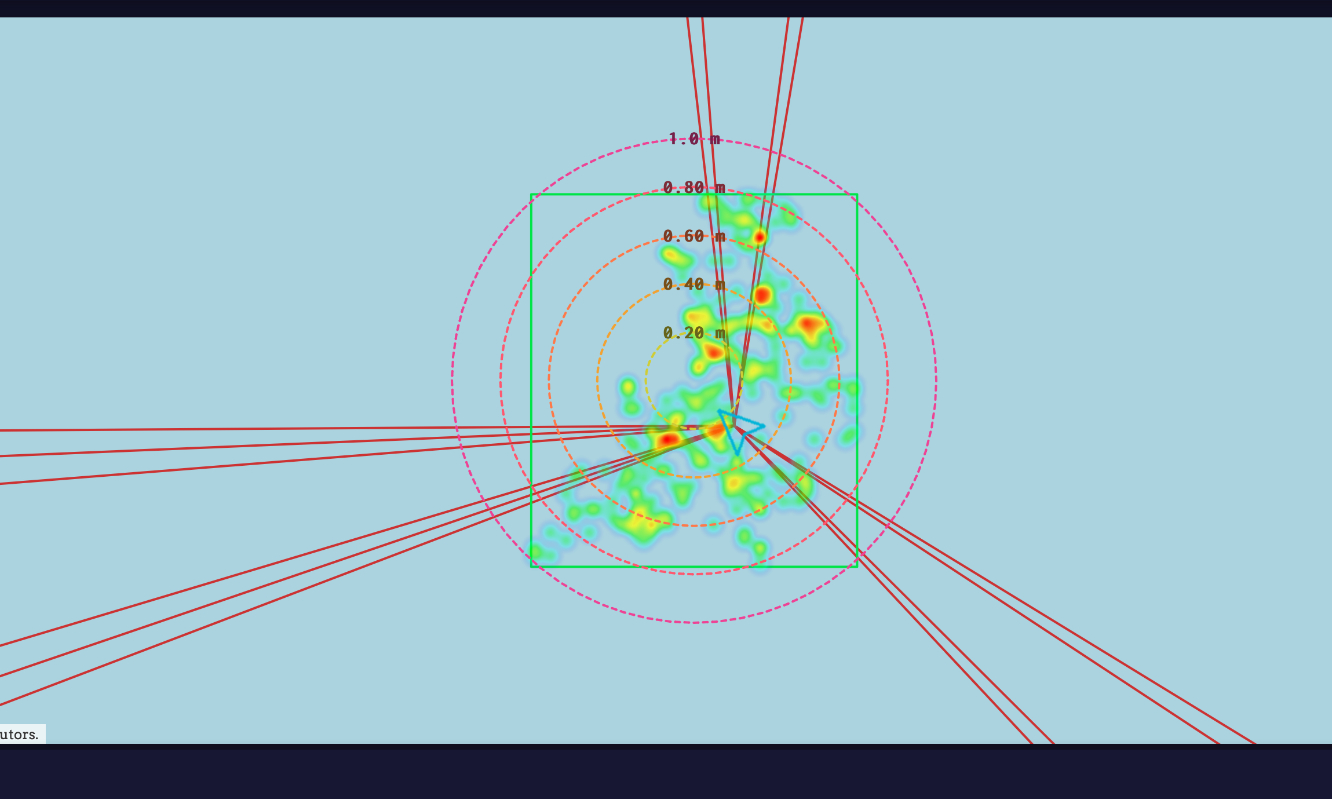

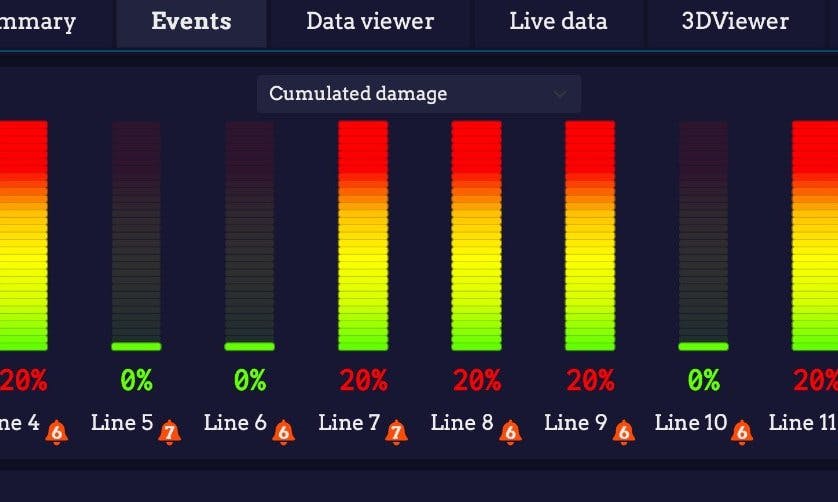

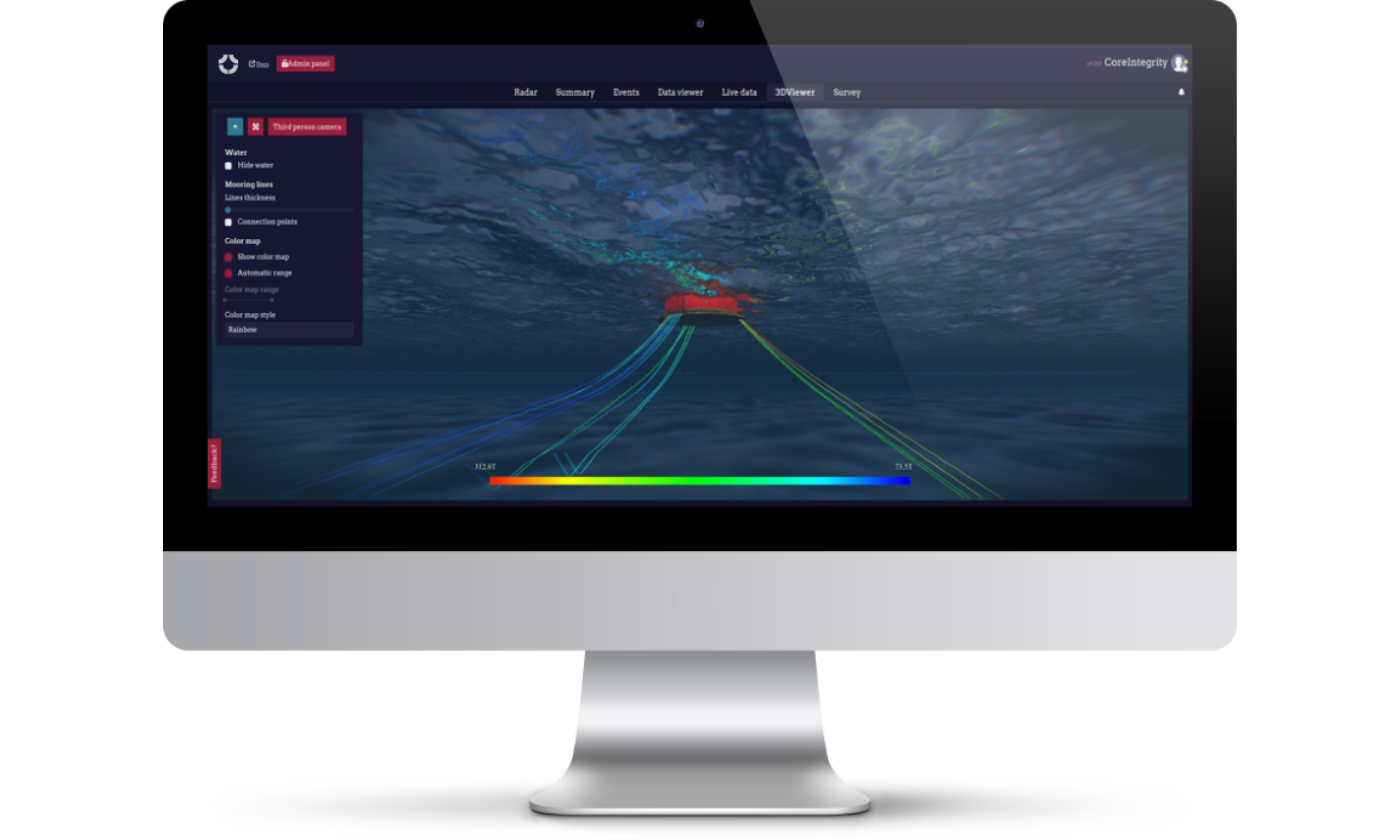

Mooring line failure is not inevitable. It can be avoided with proper mooring integrity management. This involves not only designing the mooring system according to the relevant standards and codes, but also monitoring and inspecting the mooring system throughout its operational life.

Monitoring and inspection are crucial for detecting and diagnosing any issues with the mooring system before they become critical. They can also help optimize the maintenance and repair strategies, as well as extend the service life of the mooring system.

However, traditional methods of monitoring and inspection are often costly, time-consuming, and unreliable. They rely on manual measurements, visual inspections, and periodic surveys that can miss important details or provide inaccurate data. They also require mobilizing vessels, divers, or ROVs, which can be challenging in remote or harsh locations.